HyperCyl Case Study: Clinch Studs & Clinch Nuts

Comments Off on HyperCyl Case Study: Clinch Studs & Clinch NutsA major U.S. manufacturer of automotive components contacted HyperCyl® to increase quality & speed of their finished products and free up floor space for a new assembly line. The OEM was experiencing persistent assembly interruptions due to their hydraulic Clinch Nut & Clinch Stud operations inability to monitor & relay actual insertion forces & distances. […]

Tags: Air Over Oil Cylinders, Forming, High Force, High Speed, Hydra-Pneumatic Cylinders, Hydraulic Actuators, Industrial Production, IntellyCyl, Linear Actuators, Manufacturing, Mechanical, Pneumatic Actuators, press systems, Presses

HyperCyl Case Study: Removing Hydraulics from the Equation for Assembly

Comments Off on HyperCyl Case Study: Removing Hydraulics from the Equation for AssemblyA major U.S manufacturer of braking and suspension components contacted HyperCyl® to increase quality of their finished products and free up floor space for a new assembly line. The OEM was experiencing persistent assembly interruptions due to their Hydraulic Dial Tables’ inability to monitor & relay actual insertion forces & distances. Additional floor space was […]

Tags: Air Over Oil Cylinders, High Speed, Hydra-Pneumatic Cylinders, Hydraulic Actuators, Industrial Production, IntellyCyl, Linear Actuators, Manufacturing, Mechanical, Pneumatic Actuators, press systems, Presses

HyperCyl Case Study: HyperCyl-EMA Actuator Reduces Customer Costs and Down-Time

Comments Off on HyperCyl Case Study: HyperCyl-EMA Actuator Reduces Customer Costs and Down-TimeA food grade paper tray manufacturer contacted Aries Engineering/HyperCyl® to reduce electricity expenses when replacing (20) 30-Ton hydraulic presses. Their current hydraulic cylinders were costing them approximately $180,000 in electricity yearly, not including maintenance costs and the cost of hydraulic fluid disposal. The manufacturer chose the HyperCyl-EMA®, our Electro-Mechanical Actuator, which provided a cost savings […]

Tags: Air Over Oil Cylinders, Ball Screw Actuators, Electric Actuators, High Force, High Speed, HyperCyl EMA, Industrial Production, Manufacturing, Mechanical, press systems, Presses, Roller Screw Actuators, Servo Actuators

Improving Quality and Reducing Costs In Seal Manufacturing

Comments Off on Improving Quality and Reducing Costs In Seal ManufacturingA major U.S manufacturer of steel-cased, multi-element seals contacted Aries Engineering/HyperCyl® for help in reducing excessive warranty costs of their finished product. The OEM was experiencing in excess of $10 million per year in warranty claims due to their current hydraulic presses’ inability to monitor the number of elements within a given assembly. They needed […]

Tags: Air Over Oil Cylinders, High Speed, Hydra-Pneumatic Cylinders, Hydraulic Actuators, Industrial Production, Linear Actuators, Manufacturing, Mechanical, Pneumatic Actuators, press systems, Presses

Using Cleaner Technology for a Brighter Factory

Comments Off on Using Cleaner Technology for a Brighter FactoryOutdated Hydraulic systems require constant maintenance and high cost pumps, Pure Pneumatic systems lack the force and controllability, Arbor Presses and Hammers exhaust my employees, Flywheels are dangerous; if these problems sound familiar you’re not alone. Why not use a clean, reliable, consistent & cost-effective product to REPLACE all of these? The Solution is HyperCyl! […]

Tags: Air Over Oil Cylinders, Ball Screw Actuators, Electric Actuators, High Speed, Hydra-Pneumatic Cylinders, Hydraulic Actuators, HyperCyl EMA, Industrial Production, Manufacturing, Mechanical, Pneumatic Actuators, press systems, Presses, Roller Screw Actuators, Servo Actuators

“Punching and Shearing” Tips and Tricks

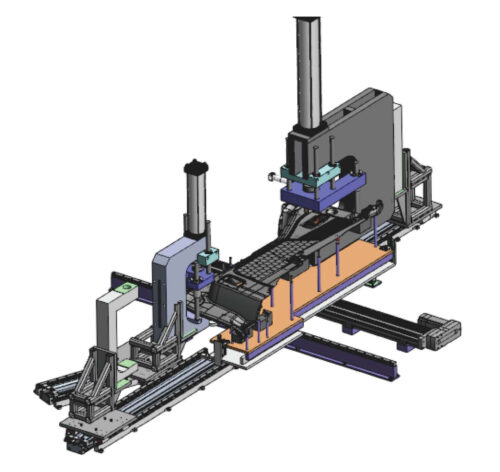

Comments Off on “Punching and Shearing” Tips and TricksAries Engineering/HyperCyl is a diversified manufacturer of Hydra-Pneumatic Cylinders, Servo Actuators, Presses, Pierce Units and Joining Systems designed for use in a wide range of assembly and forming applications. HyperCyl has a place in virtually every segment of industrial production. HyperCyl has a proven track record in thousands of applications as a clean, quiet, reliable, […]

Tags: Air Over Oil Cylinders, Forming, High Speed, Hydra-Pneumatic Cylinders, Hydraulic Actuators, Industrial Production, Manufacturing, Mechanical, Piercing, Pneumatic Actuators, press systems, Presses

HyperCyl Spotlight: UTV Applications

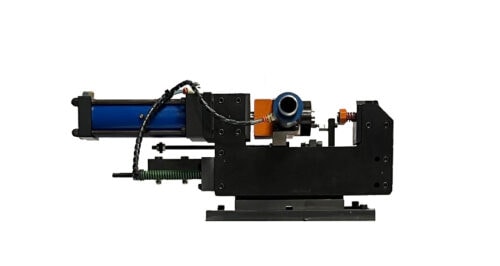

Comments Off on HyperCyl Spotlight: UTV ApplicationsRoll Cage Pierce/Form: Typical End-forming and tube Piercing of UTV Roll Cage requires an Approximate Force Range 5-40 Tons depending on the details. Piercing requires internal expanding mandrels to reach long distances inside the tube body. End-forming varies dramatically based on the needs of each application but involves forming the end of tubes to various GD&T […]

Tags: Air Over Oil Cylinders, Ball Screw Actuators, Electric Actuators, Forming, High Force, High Speed, Hydra-Pneumatic Cylinders, HyperCyl EMA, Industrial Production, IntellyCyl, Piercing, press systems, Presses

How To: Build Intelligence into Piercing for Today’s High Force/High Speed Environments

Comments Off on How To: Build Intelligence into Piercing for Today’s High Force/High Speed EnvironmentsFlexibility, performance and cost have always been key factors in today’s expanding manufacturing marketplace. For decades hydraulic and mechanical presses were the only options for high-speed, high-force Piercing Applications. HyperCyl Hydra-Pneumatic and HyperCyl-EMA servo based systems have emerged as viable alternatives geared towards today’s lean manufacturing processes. HyperCyl also provides a much cleaner solution without the […]

Tags: Air Over Oil Cylinders, High Force, High Speed, Hydra-Pneumatic Cylinders, HyperCyl EMA, Industrial Production, IntellyCyl, Manufacturing, Mechanical, Piercing, Pneumatic Actuators, press systems, Presses, Rod Locks

How To: Determine the Appropriate Technology for High Force/High Speed Applications

Comments Off on How To: Determine the Appropriate Technology for High Force/High Speed ApplicationsFlexibility, performance, capital and operating costs have always been key factors in today’s expanding manufacturing marketplace. For decades hydraulics and mechanical presses were the only options for high-speed, high-force assembly and forming applications. More recently hydra-pneumatics and servo-based systems have emerged as viable low-cost alternatives. So which technology is best suited for a specific application? […]

Tags: Air Over Oil Cylinders, Ball Screw Actuators, Electric Actuators, Hydra-Pneumatic Cylinders, Hydraulic Actuators, HyperCyl EMA, Industrial Production, Linear Actuators, Manufacturing, Pneumatic Actuators, press systems, Presses, Roller Screw Actuators, Servo Actuators

Can HyperCyl meet your application needs?

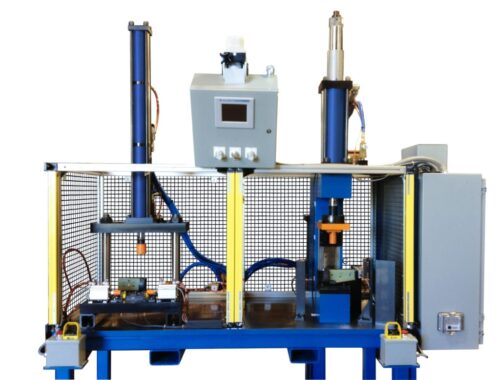

Comments Off on Can HyperCyl meet your application needs?HyperCyl’s products are designed to enable clean, quiet, and precise operations with minimal maintenance requirements. Our diverse product portfolio supports a wide range of industries and applications. Industries Aries Engineering/HyperCyl is a Michigan-based company specializing in the fabrication of cylinders, presses, and other products for assembly and forming applications in the industrial automation, manufacturing, commercial, […]

Tags: Air Over Oil Cylinders, Ball Screw Actuators, Electric Actuators, Hydra-Pneumatic Cylinders, Hydraulic Actuators, HyperCyl EMA, Industrial Production, Linear Actuators, Manufacturing, Pneumatic Actuators, press systems, Presses, Roller Screw Actuators, Servo Actuators